In any farming activity, culture site selection is of paramount importance. Technological and economic considerations play a major role in the selection process. A careful appraisal of the habits of the organism to be cultured would give a resonable level of confidence on the tolerance limits within which the various environmental parameters can vary. Due consideration has to be given to possible effects of fluctuating water flow, primary production, siltation, etc. in order to obtain the optimum level of growth and production of high quality pearls. Unsuitable levels of environmental factors such as salinity, water temperature, cold water currents and other factors such as red tides, hydrogen sulphide and pollution by industrial and domestic effluents are serious hazards to pearl culture.

Sheltered bays are ideal locations for pearl oyster farms. They offer good protection to the culture structures such as rafts and cages. Shallow coastal waters where the sea is calm most of the year can also be considered as a suitable site.

In temperate regions, the water temperature plays an important role in the biological activities of pearl oysters. In Japan, the optimum temperature for oyster growth has been found to be between 20–25 °C. A temperature below 13 °C causes hybernation. Below 6 °C, the oysters die. At temperatures above 28 °C, the oysters show exhaustion. The thickness of the pearl layers are affected by the minute changes in water temperature during the day and also vary considerably according to the season of the year. The deposition of calcium stops at a water temperature of 13 °C. In the Gulf of Kutch, the oysters grow vigorously in winter months when the seawater temperature ranges between 23–27 °C. A slight decrease in temperature triggers spawning in oysters in the Gulf of Mannar. The growth-temperature relationship is presumably valid only up to a certain temperature for optimum growth.

Pearl oysters tolerate a wide range of salinity from 24–50 ‰ for a short duration of 2–3 days. Salinities of 14 ‰ and 55 ‰ may cause a 100 % mortality among the oysters. The effect of salinity on the growth of pearl oyster has not been clearly investigated. However, it appears that pearl oysters tend to prefer high salinities. Oysters raised in such salinities produce pearls with a golden tint.

Gravelly bottoms are suitable for pearl oyster farming, while sandy or muddy bottoms should be avoided. Oyster growth is affected by water temperature and nutritional condition of the ground. Repeated culture on the same ground leads to some extent the deterioration of pearl quality. The chemical and physical state of the sea bottom is affected by the organic substances discharged from the oysters and fouling organisms. Periodic removal of such accumulated substances from the bottom of the culture grounds often increase production as well as quality.

The optimum depth for farming pearl oysters is around 15 m. At greater depths, even if the rate of nacre deposition is slower, pearls of high quality with a pinkish colouration are obtained.

Pearl oysters generally prefer clear waters as high turbidity levels will affect their filtration efficiency. A decline in oyster condition was noted at Veppalodai farm due to the high silt content in the farm area throughout most of the year.

Culture sites should be naturally sheltered against strong winds and waves. Tidal amplitude and currents must be sufficient in order to allow replenishment of oxygenated water and fresh plankton and flush away waste materials. In strong water currents the formation of the pearl layers is usually fast, but the quality of pearls produced is affected.

The condition of a specific culture ground depends primarily on the chemical constitution of the seawater and on the species and amount of plankton present. Rich nutrients discharged by rivers into the sea are responsible for high primary productivity. The oysters probably derive their chief source of conchiolin from the nitrogen substance of the plankton. The organic matter and calcium dissolved in the seawater are directly absorbed by the food consumption cells. The calcium passes through the mantle to be deposited on the surface of the shell or pearl in the process of their formation. The presence of trace metals in small quantities influences the colour of the nacre.

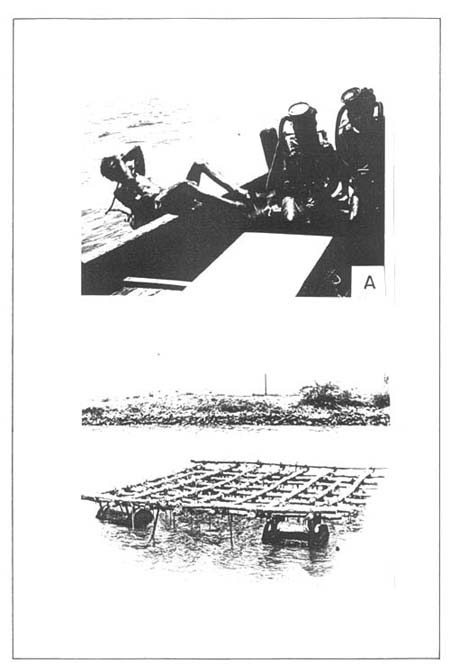

In pearl oyster farming, oysters collected from the natural beds or reared from naturally collected or cultured spat are used. In the Gulf of Mannar, several pearl banks are distributed off Tuticorn at a distance of 12–15 km and at depths of 12–25 m. Pearl oysters from these beds are collected by skin and SCUBA diving (Plate IV A). Wide fluctuations in terms of pearl oysters availability have been noted in different pearl banks in this area during the last few centuries as also during the most recent years. In the Gulf of Kutch, the pearl oysters are found on the intertidal flats and the population is sparse. Collection is done by hand.

In Japan, oyster spat are collected by submerging bundles of cedar twigs near the water surface during the peak larval settlement season. Hyzez films and old fish nets are also commonly used as spat collectors. Almost the entire requirement of oyster supply to the pearl culture industry is met by this type of spat collection. Spat collection attempts in India have not been successful, and this may be due to the distance of the pearl oyster beds from coastal waters.

However, India has recently succeeded in producing pearl oyster seed under hatchery conditions, therby providing the industry with a more dependable source of oysters.

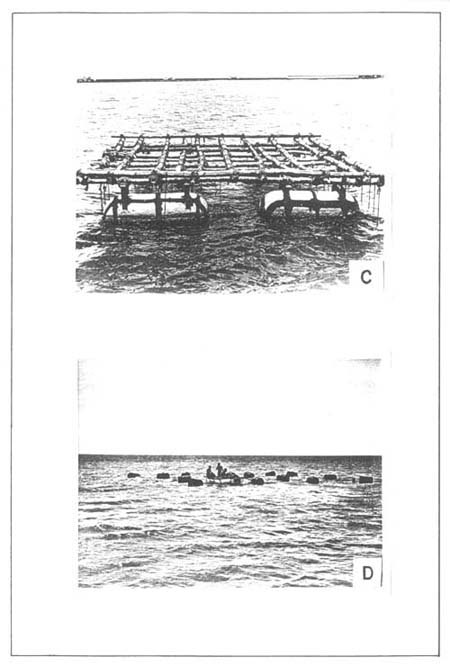

Raft culture is considered to be one of the most suitable farming methods in sheltered bays. The size of the rafts can be altered according to the convenience of the situation. A raft of 6×5 m in size can be easily constructed and floated with 4 buoys. Rafts are usually constructed with logs of teak, venteak or casuarina wood, of chosen length with the bottom of about 10 cm diameter tapering to 6 cm diameter at the tip. These logs are arranged as per the requirement and lashed with coir ropes. Floats are attached to the raft to give buoyancy. The floats can be sealed empty diesel drums of 200 l capacity with fibreglass coating, mild steel barrels painted with antisaline/anticorrosive paints or FRP styrofoam floats (Plate IV B and C). Unit raft system is found to be convenient and well suited to the Indian sea conditions. Rafts are moored with anchors at opposite sides with tested quality chains and their direction is decided according to the prevalent wind direction at the specific site (Fig. 4 A-C).

In the long-line culture method, spherical or cylindrical floats which are connected by horizontal synthetic rope or chain are used (Plate IV D; Fig. 4 D). The oyster cages are suspended from the ropes. This system is good for open sea conditions. In another method of hanging, a hole is drilled near the hinge of the pearl oyster. A small thread is put through the hole, which is then tied to a straw rope coated with tar. The straw ropes are hung from a raft.

Sea bottoms with a granite or coral stones composition can be used for on-bottom culture. In the Tuticorin Harbour Basin where the breakwater has been constructed with granite stones, the protected portion of the breakwater is used for culturing mother oysters. 1 m of water is available below the low water mark. Due to constant circulation of seawater, settlement of fouling organisms is poor and inconsistent. However, it has been noted that the growth of the mother oyster is slower in on-bottom culture compared to the growth of oysters cultured in raft.

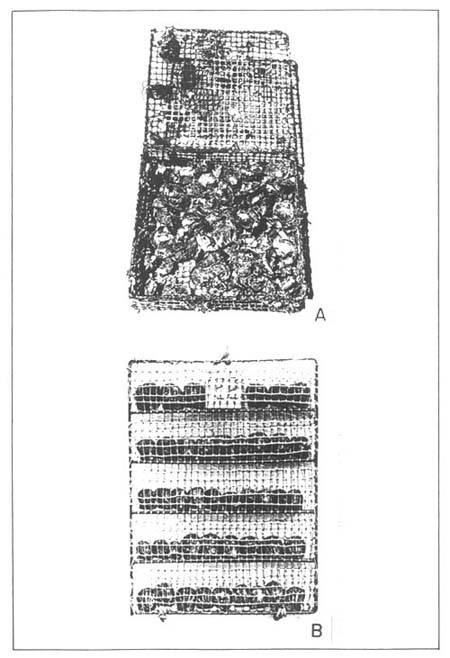

Box cages, measuring 40×40×15 cm, are used to rear mother pearl oysters. The size of the mesh varies with the size of the oysters to be reared. The frames of the cages are made up of 6 mm mild steel rods, coated with anticorrosive paints or coal tar. Box-cages are useful in general mother oyster culture (Plate V A).

To trace the history and performance of individual oysters, frame nets are used. The frames, measuring 60×40 cm each with five compartments, meshed and hinged at one end, open as a book. The oysters are arranged in rows and held in the compartments when closed. The space available in between the two frames is about 10 mm which is sufficient for the oysters to open their valves for feeding and respiration (Plate V B).

PLATE IV. (A) A scuba diver diving to collect pearl oysters and (B) A culture raft floated with mild steel barrels.

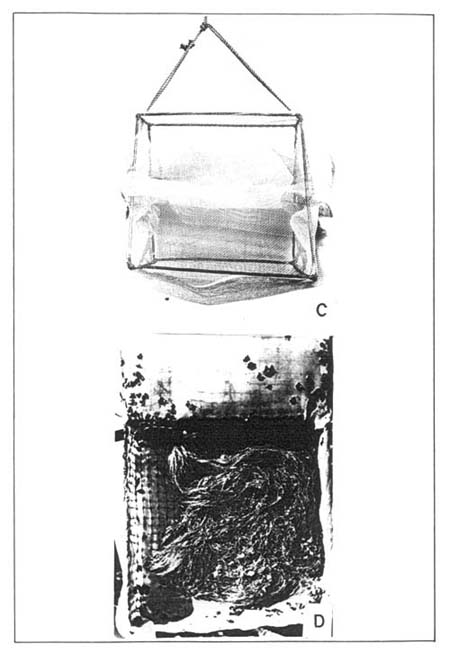

PLATE IV. Cont'd. (C) A culture raft with FRP styrofoam buoys and (D) Oyster long-line culture.

FIGURE 4. (A) Culture raft constructed with teak poles; (B) A FRP styrofoam buoy; (C) A mild steel buoy, and (D) Oyster long-line culture system.

Juvenile pearl oysters are reared in netcages (Plate V C-D). Synthetic fabric of velon screen bags whose sides are stretched with a steel rod in the form of a prism are used for rearing of juveniles. The mesh size of the screen depends on the size of juveniles to be reared. The mouth of the bag is tied with a synthetic twine which facilitates opening or closing when required. To provide further protection from predators the bags are placed in old nylon fish net bags. Clogging by silt and by the growth of fouling organisms can be prevented by periodical replacement of the velon screen bag which can be cleaned, sun-dried and reused. Spat of up to 2 cm in size are reared in these small netcages. Box-cages which are used for rearing mother oysters can also be used for juvenile rearing by providing an additional velon screen cover inside the cage.

PLATE V. (A) A box-cage containing pearl oysters and (B) A frame netcage with oysters.

PLATE V. Cont'd. (C) A netcage for rearing oyster spat of 3–10 mm in size and (D) Rearing netcage covered with velon screen.